Advancements in Catalytic Combustor Technology: Improving Efficiency and Reducing Emissions

Introduction

Advancements in catalytic combustor technology play a crucial role in reducing emissions and improving energy efficiency in various industries. Catalytic combustors are devices that utilize catalysts to enhance the combustion process, promoting efficient reduction and oxidation reactions. These advancements have significant implications for sustainable energy production and addressing environmental concerns. This article will explore the recent advancements in catalytic combustor technology, their impact on efficiency and emissions reduction, applications, future prospects, and developments.

Recently, a growing focus has been on developing catalytic combustor technology to address the challenges of reducing emissions and improving energy efficiency. The use of catalytic converters in various industries, such as automotive and power generation, has become widespread. These devices have proven to be effective in reducing the emissions of harmful pollutants. As a result, legislation has been enacted to regulate emissions and promote the use of catalytic converters. In recent years, there have been significant advancements in catalytic combustor technology, including improvements in cold start performance, substrate design, and catalyst materials. These advancements have led to increased efficiency and reduced emissions in combustion processes.

Evolution of Catalytic Combustor Technology

The development of catalytic converters in the mid-1970s marked a significant milestone in the fight against pollution and improving air quality. Initially, the automotive industry resisted the implementation of catalytic converters. However, these devices have now become widespread worldwide. Catalytic converters have played a pivotal role in improving major cities' air quality by reducing harmful pollutants emissions. Over the years, legislation has been enacted to address air pollution and regulate emissions from various sources, including power stations and internal combustion engines. The recognition of the need for catalytic converters to remove pollutants from gasoline vehicles dates back to 1909.

The evolution of catalytic combustor technology can be attributed to the continuous efforts to reduce emissions and improve energy efficiency. Initially, catalytic converters were primarily used in automotive applications. However, their effectiveness in reducing emissions led to their adoption in other industries, such as power generation and heating systems. The development of catalytic combustors has been driven by advancements in catalyst materials, substrate design, and combustion optimization techniques. These advancements have resulted in improved efficiency and reduced emissions in combustion processes.

Recent Advancements in Catalytic Combustor Technology

Recent advancements in catalytic combustor technology have focused on enhancing the performance of catalytic converters in reducing emissions from internal combustion engines. Two-way catalytic converters are used in diesel engines, while three-way catalytic converters are employed in gasoline engines. Strategies to improve cold start performance, such as heating systems and air injection, have been implemented. The design of the substrate and the choice of catalyst materials, including noble metals like palladium and platinum, significantly influence the efficiency of catalytic converters. Additionally, the oxygen storage capacity of catalytic converters plays a vital role in ensuring efficient catalytic combustion. Numerical simulations are employed to study and optimize the performance of catalytic converters, enabling researchers to estimate species conversion, flow distribution, and other essential parameters.

In recent years, there have been significant advancements in catalytic combustor technology to improve catalytic converters' efficiency and emissions reduction capabilities. One of the key areas of focus has been the development of new catalyst materials with improved performance and durability. Researchers have been exploring the use of non-noble metals and metal oxides as catalysts, which can offer similar or even better catalytic activity compared to noble metals. These alternative catalyst materials can potentially reduce the cost of catalytic converters and make them more accessible for widespread adoption.

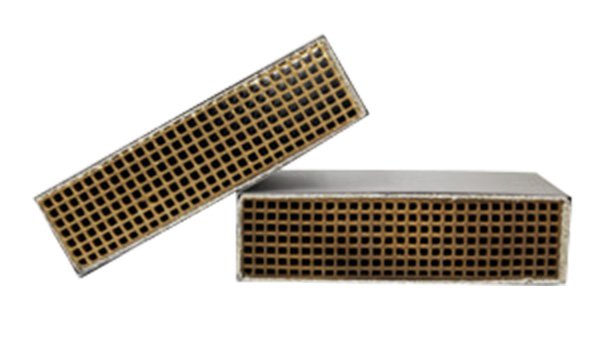

Furthermore, advancements in substrate design have contributed to improved performance and efficiency of catalytic combustors. The design of the substrate plays a crucial role in providing a large surface area for the catalyst to interact with the exhaust gases, enhancing the conversion of pollutants. Researchers have investigated various substrate materials and structures to optimize the catalytic performance, including advanced ceramics and honeycomb structures. These advancements in substrate design have led to higher conversion efficiencies and improved durability of catalytic converters.

In addition to catalyst materials and substrate design, advancements in combustion optimization techniques have also contributed to improving catalytic combustor technology. Numerical simulations and computational fluid dynamics (CFD) models are now widely used to study and optimize the performance of catalytic converters. These simulations enable researchers to understand the complex flow and reaction dynamics within the catalytic converter, leading to better design and optimization of the catalyst geometry, flow distribution, and thermal management. Using these advanced simulation techniques, researchers can evaluate the performance of different catalytic combustor configurations and optimize them for maximum efficiency and emissions reduction.

Recent advancements in catalytic combustor technology have focused on improving catalytic converters' performance and efficiency by developing new catalyst materials, substrate design, and combustion optimization techniques. These advancements have the potential to reduce emissions further and improve energy efficiency in various industries, contributing to a more sustainable and environmentally friendly future.

/1003/site-assets/logo.png)